Product Code : 3D-NiCrFeBSiCuMo-CU-PO

Nickel chromium iron boron silicon copper molybdenum alloy powder is a nickel based self fluxing alloy powder mainly composed of nickel powder, with a certain proportion of chromium powder, iron powder, boron powder, silicon powder, copper powder, and molybdenum powder added.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Product Information

Nickel chromium iron boron silicon copper molybdenum alloy powder is a nickel based self fluxing alloy powder mainly composed of nickel powder, with a certain proportion of chromium powder, iron powder, boron powder, silicon powder, copper powder, and molybdenum powder added.

The so-called self fluxing alloy refers to an alloy material that contains deoxygenated elements such as boron and silicon and has a low melting point. During the heating and melting process, the composition of the alloy can reduce the oxides of itself and the substrate, forming a low melting point borosilicate slag to cover the surface, preventing the oxidation of the alloy and improving its wetting performance, so as to achieve good metallurgical bonding between the alloy and the substrate. The bonding strength between the welding layer of self fluxing alloy and the substrate is generally 30-50kgf/mm2 (300-500Mpa). According to different chemical compositions, welding layers with different hardness of HRC15-65 can be obtained.

Nickel chromium iron boron silicon copper molybdenum alloy powder is a common nickel based self fluxing alloy powder. It has low melting point, good self melting ability, and comprehensive properties such as wear resistance, corrosion resistance, heat resistance, and oxidation resistance, making it the earliest and most widely used self melting alloy powder.

Chemical Composition of Nickel Chromium Iron Boron Silicon Copper Molybdenum Alloy Powder

| Spec. | Hardness (HRC) | Chemical Composition |

| NiCrFeBSiCuMo-60 | 60 | Cr 16%, Fe 5%, B 4%, Si 4%, Cu 3.2%, Mo 3%, C 0.9%, Ni balance |

| NiCrFeBSiCuMoW-65 | 65 | Cr 16%, Fe 5%, B 4%, Si 4%, Cu 3.2%, Mo 3%, W 3%, C 0.9%, Ni balance |

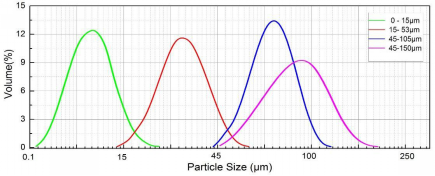

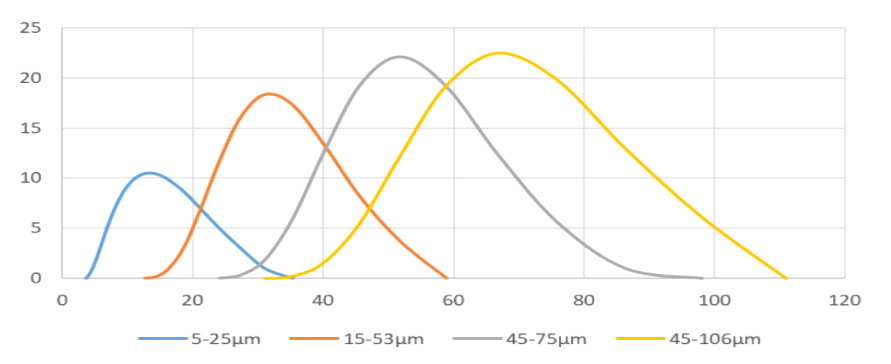

Spherical Nickel Chromium Iron Boron Silicon Copper Molybdenum Alloy Powder Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Various granularities can be customized according to customer requirements)

Spherical Nickel Chromium Iron Boron Silicon Copper Molybdenum Alloy Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Spherical Nickel Chromium Iron Boron Silicon Copper Molybdenum Alloy Powder Characteristics

high purity (≥ 99.9%), low oxygen (≤ 1000ppm), high sphericity (≥ 98%), uniform grain distribution, excellent mobility energy (≤10.0s/50g), high loose loading density (≥ 6.0g/cm3)

Spherical Nickel Chromium Iron Boron Silicon Copper Molybdenum Alloy Powder Applicable Processes

Laser/electron beam additive manufacturing (SLM/EBM), laser direct deposition (DLD), powder thermal and other static pressure forming (HIP), metal injection forming (MIM), powder metallurgy (PM), laser melting application (LC), etc.

Spherical Nickel Chromium Iron Boron Silicon Copper Molybdenum Alloy Powder Application

Nickel chromium iron boron silicon copper molybdenum alloy powder has low melting point, good self melting ability, and comprehensive properties such as wear resistance, corrosion resistance, heat resistance, and oxidation resistance. It is mainly used in the following situations and fields:

1. Nickel chromium iron boron silicon copper molybdenum alloy powder can be used for spray welding, atmospheric or water stable plasma spraying;

2. Nickel chromium iron boron silicon copper molybdenum alloy powder can be used for HVOF / HVAF supersonic flame thermal spraying.

Packing of Spherical Nickel Chromium Iron Boron Silicon Copper Molybdenum Alloy Powder

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Spherical Nickel Chromium Iron Boron Silicon Copper Molybdenum Alloy Powder is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.